|

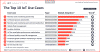

Top 10 IoT Use Cases report from IoT Analytics, published

October 2021. These use cases include remote asset monitoring,

process automation, vehicle fleet management, optimizing plant

or asset performance, and more. All 10 use-cases share certain

network requirements, like cybersecurity, tolerance for harsh

environmental conditions, and a way to scale management as the

deployment grows. But other network requirements vary based on

the use case.

Here are some questions to help you identify network

requirements for your IoT use cases.

Are your

connected assets stationary or moving? How much data will they

transmit?

If you’re

connecting stationary assets, the main considerations are:

-

Bandwidth: You’ll need more if your devices generate

lots of data (e.g., point-tilt-zoom HD cameras) or if you’re

backhauling data from many devices.

- Type of

network: Depending on what’s available, you might

connect assets to a wired network, Wi-Fi, 3G, public or

private LTE, 5G, wireless backhaul, etc. To avoid the

complexity of managing different kinds of routers, look for

one that gives you a choice of communications modules.

-

Reliability: If your use case is mission-critical,

you’ll need ultra-reliable connectivity. A dropped

connection that halts operations can cause financial loss.

It gets more

complicated when we think about connected assets that are in

motion— for example, Wi-Fi hotspots on trains, environmental

sensors on trucks transporting perishables, or

container-handling equipment at ports. Network requirements in

these use cases include low latency and seamless hand-offs

between wireless networks. If you’re connecting moving equipment

– for example, robots, cranes, autonomous vehicles, etc. in

warehouses, ports, and mines – ultra-high reliability is crucial

to prevent accidents.

Is sensor data

used for real-time decisions?

If so, you’ll

need a highly responsive network, with low latency. For example,

think about tele-remote operation of vehicles in ports and

mines, where an operator in the office remotely controls a

vehicle while viewing real-time video feeds from a

vehicle-mounted camera. Delays in the video feed can mean the

operator misses a turn or obstacle, causing an accident. In

contrast, if you’re simply checking that perishables in a truck

weren’t exposed to unsafe conditions during the trip, a little

latency won’t make a difference.

Common

denominators: cybersecurity, remote management, rugged

enclosures

No matter how

you’re using industrial IoT, some network features are

mandatory. Security protections are one. Cyberattacks can cause

downtime, revenue loss, worker safety issues, quality problems,

and disruption of critical infrastructure services.

Cisco Blogs / Internet of Things (IoT).

|